At PRNZ, we focus on processing post-industrial and post-consumer plastic waste into high-quality recyclate resins that are reintegrated into new manufacturing applications. Our primary aim is to close the loop on uPVC and HDPE materials, ensuring they are reused rather than downcycled. This approach supports a circular economy and reduces the need for virgin plastic production.

We rely on segregated feedstock to reduce the need for sorting on-site. Materials must be pre-separated before arrival to ensure streamlined processing.

Once received, materials are shredded into uniform pieces.

Our high-speed washing systems remove contaminants, preparing the plastics for granulation.

The shredded plastics are granulated into pellets of the right size. This step ensures they are ready for further manufacturing into new products.

The recyclate is used by Aliaxis to create uPVC and HDPE products, such as pipes. This process supports a more sustainable circular economy.

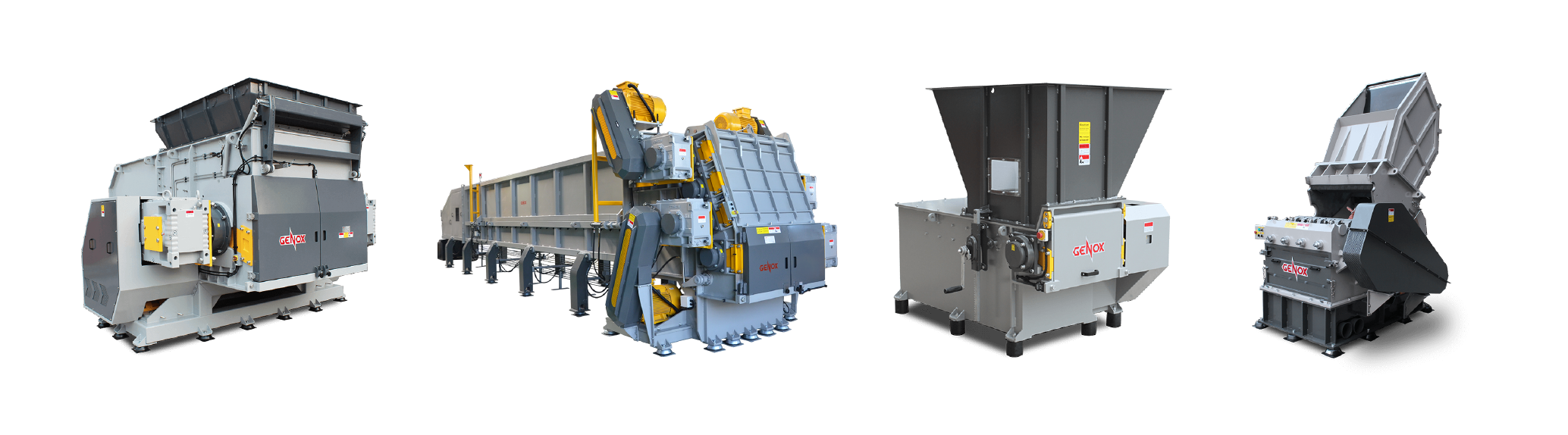

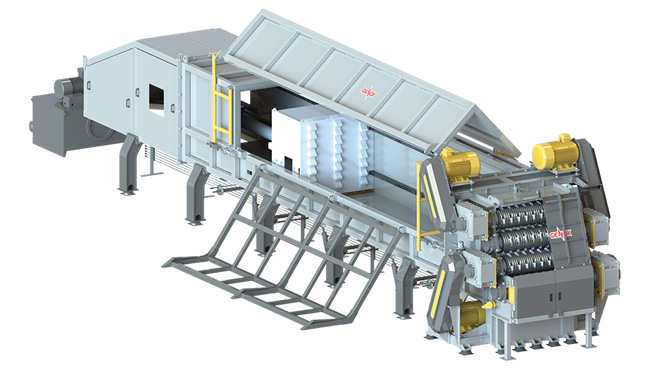

To achieve the highest standards of recycling, we use advanced machinery at our Maurice Road facility, including the J Series large pipe shredders and high-efficiency washing systems.

Our J1200 Pipe Shredding system is designed for large plastic pipes with up to 6-meter lengths and 1200 mm diameters. This multi-rotor machine features:

Our HDPE washing line is built to handle a variety of rigid plastics, including bottles and containers. Key features include:

Our PVC pipe shredding system, similar to the J Series, processes a wide range of PVC pipes efficiently with adjustable features for different material types.

The BH Series is a heavy-duty shredder designed for handling untreated waste material streams, turning them into coarse or medium-sized fractions for further processing.

These granulators are capable of handling high-throughput processing and are designed to deal with tough materials like profiles, thick sheets, and flexible materials such as films and woven bags.

uPVC and HDPE are highly durable materials that can last for up to 100 years in building and infrastructure applications. By recycling these plastics and reintegrating them into new products, we significantly reduce the need for virgin materials, contributing to a more sustainable future.

Our investment in recycling infrastructure — including the upcoming facilities in Auckland and Canterbury — is part of our commitment to reducing plastic waste in New Zealand.

PRNZ is a reliable, environmentally responsible solution for businesses managing uPVC and HDPE waste. Our recycling services support:

Recycling plastic waste from infrastructure projects.

Processing plastic pipes and farm waste.

Recycling conduit and wiring components.

PRNZ is establishing collection and consolidation services in key areas to make recycling plastics easier for businesses.

at Penrose (Auckland) or Hornby (Christchurch) facilities

Forklift or self-unloading vehicle required at processing sites.

Enclosed, lightweight plastics require specific transport solutions.

On-site services for large volumes.

Have questions or are interested in our services? Contact us today to support sustainable plastic recycling and a circular economy.

Get in Touch

PRNZ is proud to collaborate with organisations that drive meaningful change in plastic recycling. Let us know how we can help.

Collaborate With Us